Quality

During the assembly of a plywood, resin coated core

veneers are placed along with dry wood panels. The

assembled core and panels are then placed in hydraulic

hot press at defined temperature and pressure. when

pressure is applied then resin should penetrate the core

and panel vertically for stronger bonding.

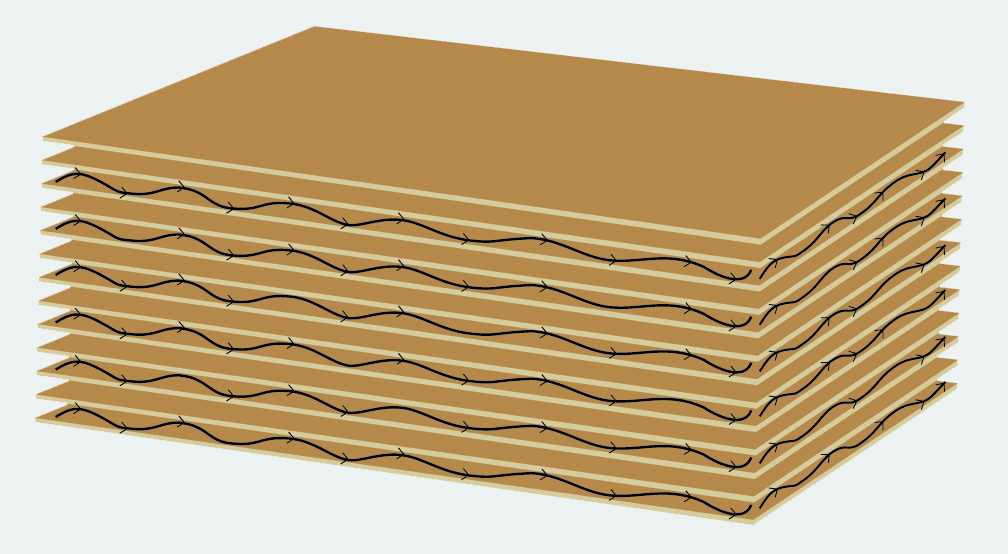

In a normal plywood, which is bonded with faulty resin,

the movement of resin occurs in horizontally not

vertically which result the poor bonding of core and

panel. Plywood made with this process have poor

strength and minimum life.

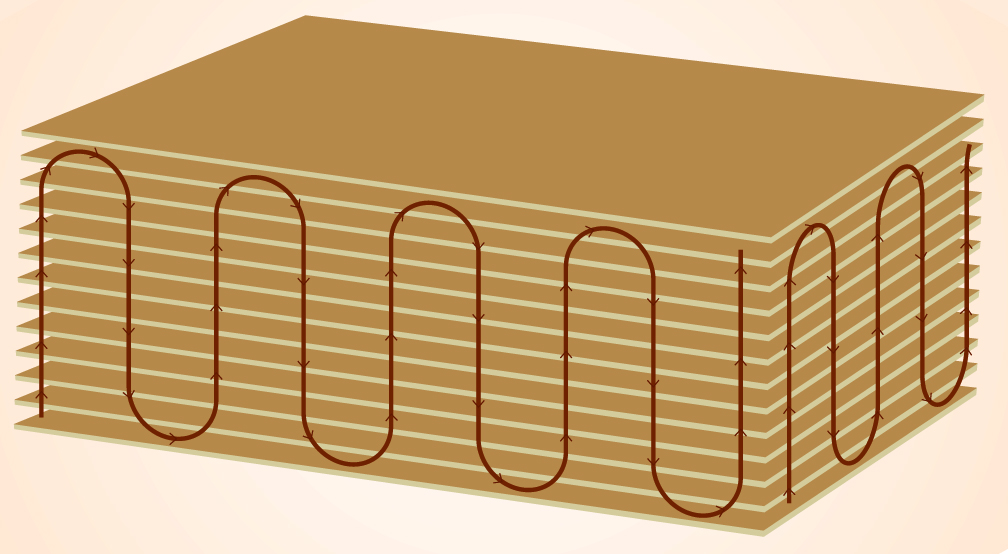

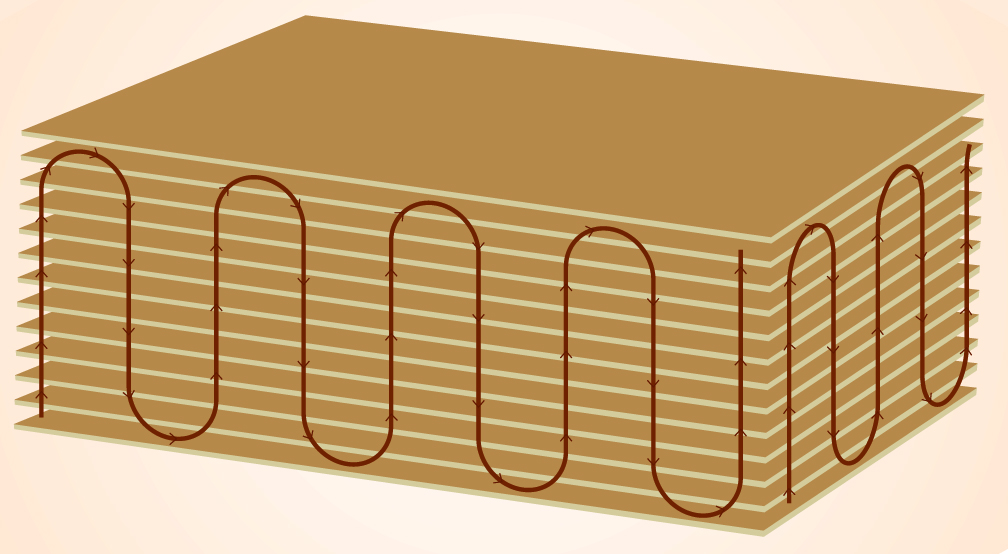

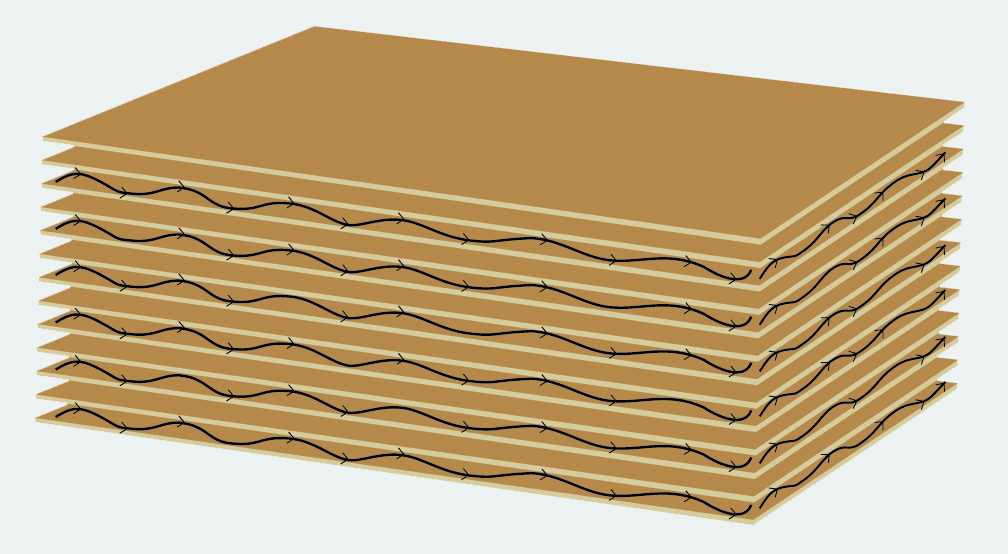

DURBI plywood is made with DRIP( Deep Resin Infusion

in Panels) technology. In this technique the resin is made

with specific formulation due to which resin has high

solid content and specific viscosity. Due to specific

viscosity resin circulate vertically in core and panel and

provide a super strong bonding between core and panel.

Due to DRIP technology resin circulate 360 degree and

provide long life and strength to plywood.

STRONGLY BONDED WITH

Durbi Ply with 360 degree resin circulation:

- Resin penetrates the core and panel and binds both

firmly, which provide strong bonding between core &

panels.

- With 360 degree resin circulation, DURBI ply has higher

binding and thus it remains strong for years.

- Uniform resin circulation provides the better water

resistant properties to DURBI ply and also remains

unaffected in high heat and humid conditions.

- 360 degree resin circulation prevent DURBI ply from

bending and twisting in changing weather conditions.

- Strong bonding, due to 360 degree resin circulation, gives

you multiple choice of painting, polishing, laminate or

veneer pasting without any de-lamination of face veneer.

Other Ply without 360 degree resin circulation:

- Resin remains on the surface of core and panels so

there is poor binding between core & panels.

- Because of poor penetration of resin normal ply core

panel and face veneer get separated after some time

- The Ply with poor binding can't withstand in water and

high humid conditions.

- Due to the uneven resin circulation normal ply have a

problem of bending and twisting.

- Face veneer get de-laminated during the painting,

polishing and laminate or veneer pasting.