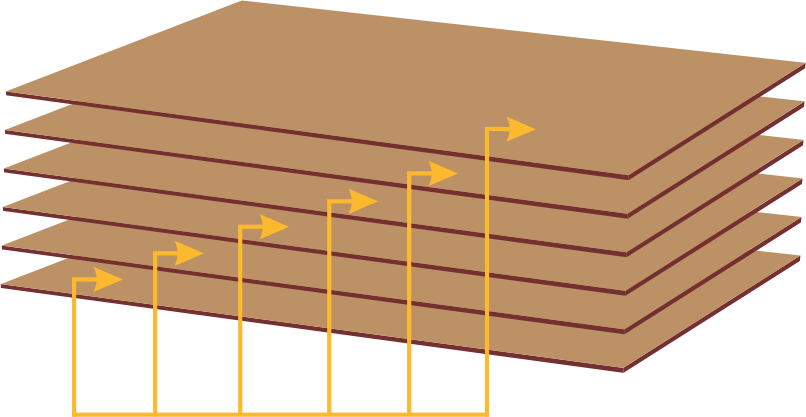

As we all know that a plywood is made with alternate gluing of panels. This practice sometimes cause poor bonding in plywood which results de-lamination of ply when it is exposed in moisture.

To overcome this problem FLEET ply is manufactured by gluing of its all layers that results in high bonding strength of FLEET Muscular Marine plywood.

In normal plywood production, gluing assembly and pressing of plywood is done at the same time. Due to this traditional practice a lot of problem arises like steam pocket, bending of plywood , glue spot on face, de-lamination of face and core etc.

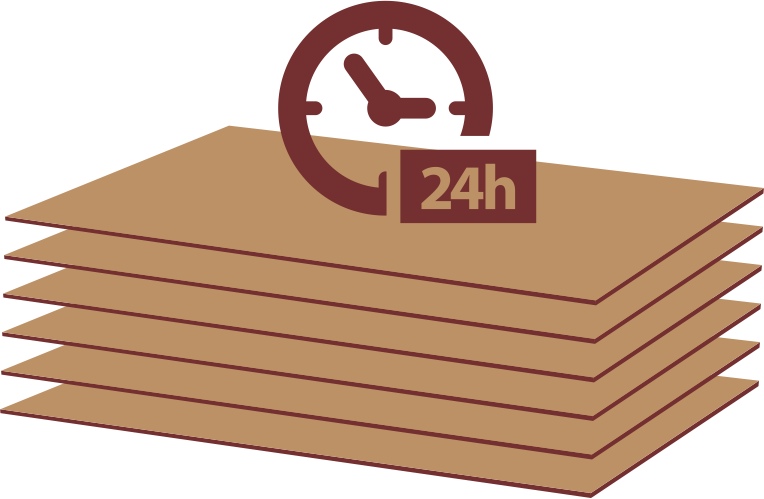

To overcome this problem we do gluing of core veneers one day before of plywood production which results in complete absorption of glue inside the veneer and it gives super strong bonding.

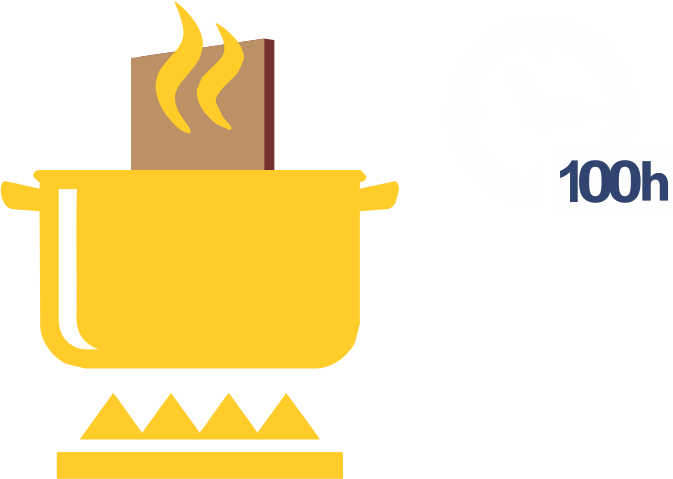

Whatever we do to make a Muscular marine Plywood is confirmed by our quality control inspectors. FLEET Muscular Marine plywood is tested in modern lab by IPIRTI scholar for its water proofing strength and we surprise that FLEET plywood confirms the 100 hour boiling test.